Izinhlobo zebhande le-sanding elifanele ukupholisha amatshe nokugaya

I-alumina ehlanganisiwe ensundu iyi-corundum yokwenziwa ekhiqizwa ngokuncibilika nokunciphisa izinto ezintathu zokusetshenziswa: i-bauxite, i-carbon material kanye namafayili ensimbi esithandweni somlilo se-arc kagesi.Ingxenye yamakhemikhali eyinhloko yi-AL2O3, okuqukethwe kwayo okungu-95.00% -97.00%, kanye nenani elincane le-Fe, Si, Ti, njll.

I-Silicon carbide iyinto engaphili enefomula yamakhemikhali ye-SiC.Yenziwa ngokuncibilika kwezinga lokushisa eliphezulu kwezinto ezingavuthiwe ezifana nesihlabathi se-quartz, i-petroleum coke (noma i-coke yamalahle), nama-wood chips (usawoti uyadingeka ukukhiqiza i-silicon carbide eluhlaza) ngokusebenzisa isithando somlilo sokumelana.Kunezinhlobo ezimbili eziyisisekelo ze-silicon carbide, i-silicon carbide emnyama ne-silicon carbide eluhlaza, zombili ezingeze-α-SiC.

Izici zamatshe ahlukene

1. Imabula yenziwe ngesisekelo se-limestone.Ingaphezulu layo linezinto ezinhle zokuhlobisa ngemva kokugaywa nokupholishwa.Kodwa-ke, impahla yayo ithambile kakhulu futhi ithinteka kalula ukuphazanyiswa kwangaphandle.

2. Ungqimba olungaphezulu lwegwadle luqinile futhi luyingxenye yedwala lentaba-mlilo, futhi lukwazi ukumelana nokugqokwa okuhle kakhulu nokumelana nokugqwala.Ivamise ukusetjenziswa emakhakheni wekhishi noma phansi.

3. Itshe lokwenziwa kwe-Inorganic alinawo ama-athomu ekhabhoni ngaphakathi, ngakho-ke ubulukhuni balo bungcono kunetshe lokwenziwa lemvelo.

4. Ukuminyana kwetshe lokwenziwa kwemvelo kuphezulu, ngeke amunce amanzi kalula, futhi anomsebenzi wokuvala kahle, futhi izinga lokusikhipha lingcono kuneletshe lokwenziwa le-inorganic.Kodwa-ke, ukuthungwa kufana nepulasitiki futhi kuzothinteka ngokunwetshwa kokushisa nokunciphisa.

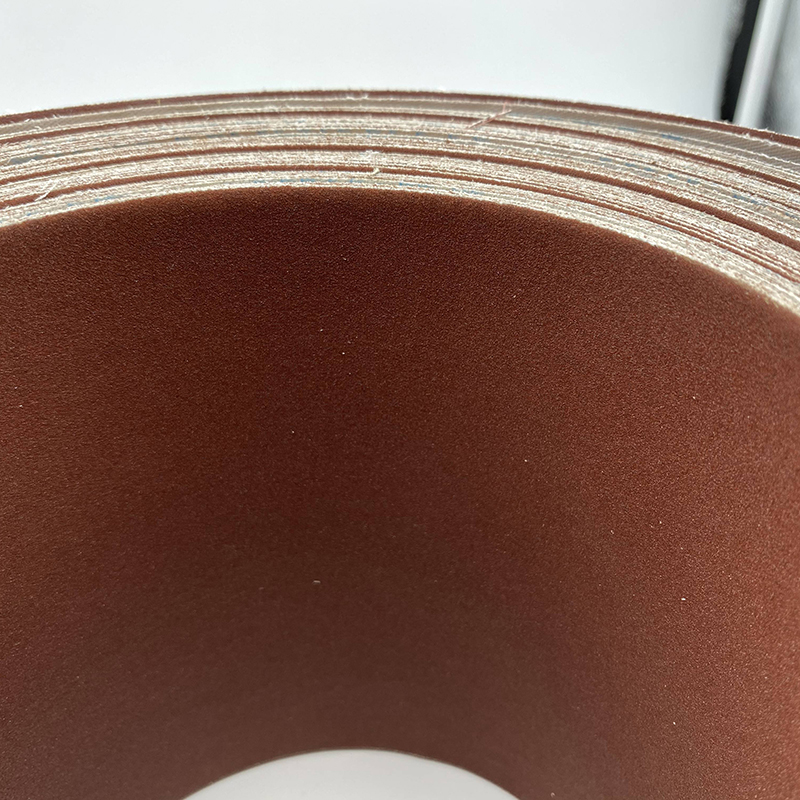

Isisekelo sebhande le-abrasive kumele sibe namandla athile kanye ne-elongation encane.

Amandla ezinto eziyisisekelo ahlobene eduze namandla ebhande eliqhumayo.Ngamandla aphezulu kuphela, ibhande elihlabayo lingakwazi ukumelana nomthelela womthwalo oqinile, umthwalo oshintshanayo, umthwalo wokugaya kanye nomthwalo wokunweba ngesikhathi sokugaya.

Ukwelulwa nakho kuyinkomba ebaluleke kakhulu yezinto eziyisisekelo.Uma ibhande le-abrasive likhula kakhulu ngaphansi kwesenzo samandla angaphandle, izinhlayiya ezihlukumezayo zizowa futhi zilahlekelwe ikhono lokugaya.Isandiso eseqile sizodlula ububanzi obulungisekayo bebhande elihuqayo legrinder.Ngenxa yalokho, ibhande le-abrasive alikwazi ukusetshenziswa.

Indlela Yokupholisha

1. Uhlobo lwesondo lokuxhumana

Ibhande elilumayo liyagaya ngokuthinta i-workpiece enesondo lokuxhumana.Ingasetshenziselwa ukucubungula umbuthano wangaphandle, imbobo yangaphakathi kanye nendiza ye-workpiece, futhi isondo lokuxhumana lingenziwa libe yisimo esithile ukwenza ubuso obugobile be-workpiece.Ukugaya ngamasondo okuxhumana antantayo nakho kungasetshenziselwa ukuhambisana nokucubungula amaphrofayili angajwayelekile.

2. Uhlobo lwepuleti lokugaya

Ngesikhathi sokugaya, ibhande elilumayo lithinta ucezu lokusebenza ngepuleti lokugaya elicindezelayo.Ipuleti yokugaya ingcindezi inomphumela wokucindezela futhi ngokuvamile isetshenziselwa ukucubungula indiza, engandisa indawo yokuxhumana, ithuthukise ukusebenza kahle kokugaya kanye nokunemba kwejometri ye-workpiece, ikakhulukazi flatness.

3. Isitayela esikhululekile

I-workpiece ixhumene ngqo nebhande elihuqekayo eliguquguqukayo ngaphandle kwanoma iyiphi into esekela ibhande eliqhumayo.Isebenzisa ukuguquguquka kwayo ngemva kokuba ibhande licindezelekile ukuze ligaye noma lipholishe ucezu lokusebenza.Le ndlela kulula ukuzivumelanisa ne-contour ye-workpiece ngaphakathi kwebanga elithile, ikakhulukazi ukwakheka okungavamile kwe-workpiece, futhi isetshenziswa kakhulu ekucubunguleni indawo yokubumba yangaphandle kanye ne-chamfering, deburring, polishing nezinye izinqubo.